Introduction to IoT in Industrial Automation

The Internet of Things (IoT) is transforming industrial automation by enabling smarter, more efficient manufacturing processes. By connecting machines, devices, and systems, IoT facilitates real-time data exchange, leading to unprecedented levels of productivity and efficiency.

Key Benefits of IoT in Industrial Automation

IoT brings numerous advantages to industrial automation, including:

- Enhanced operational efficiency through real-time monitoring and control

- Reduced downtime with predictive maintenance

- Improved safety by monitoring hazardous conditions

- Greater flexibility in manufacturing processes

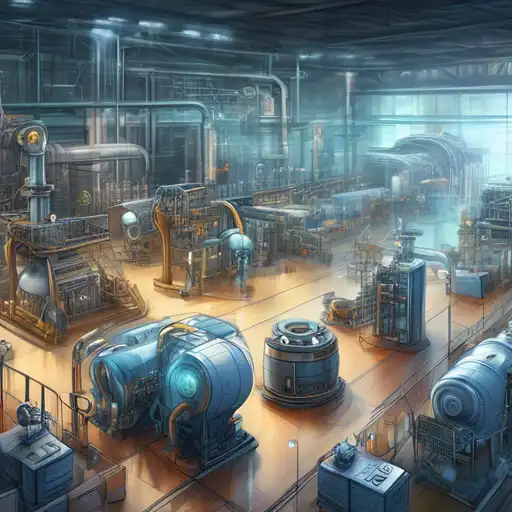

Real-World Applications of IoT in Industrial Automation

From smart factories to automated supply chains, IoT is making its mark. Examples include:

- Smart sensors for monitoring equipment health

- Automated guided vehicles (AGVs) for material handling

- Energy management systems for sustainable operations

Challenges and Solutions

Despite its benefits, integrating IoT into industrial automation presents challenges such as security concerns and interoperability issues. Solutions include adopting robust cybersecurity measures and standardizing communication protocols.

Future Trends

The future of IoT in industrial automation looks promising, with trends like edge computing and AI integration paving the way for even smarter factories. These advancements promise to further enhance efficiency, reduce costs, and improve product quality.

For more insights into the future of manufacturing, explore our Industry 4.0 section.

Conclusion

IoT is undeniably revolutionizing industrial automation, offering benefits that were unimaginable a few decades ago. As technology continues to evolve, the potential for further innovation remains vast, promising a future where smart factories are the norm.